Which AR-15 Twist Rate is Best?

Posted by 80-Lower.com on Jun 30th 2025

This guide covers all the important aspects of the AR-15 barrel: Rifling, forging, and barrel steel, treatments and coatings, and the best barrel lengths and twist rates for the most popular cartridges.

What is a "Twist Rate," Exactly?

A barrel's twist rate describes how tightly a gun barrel's rifling twists. The rifling rotates the bullet as it travels through the bore, giving it a high rate of spin in flight, which greatly improves accuracy. Think of the bullet like a football in flight. The quarterback's hands are the rifling, and how quickly they spin the ball as it leaves their hand is the twist rate.

How Rates Are Measured

Twist rates are measured in inches per 360-degree rotation, which is expressed as a ratio. For example, a barrel with a 1:7 twist rate means the rifling completes a full rotation every seven inches. A 1:10 rate means the rifling rotates once every 10 inches. The smaller the second number, the more often the rifling twists.

Twist Rate vs. Bullet Weight

Twist rate determines what bullet weight is best to shoot. Heavier bullets require fast twist rates ("more spin") to stabilize them in flight. Lighter bullets require slower rates. Cartridges are advertised based on their bullets' grain weight, like "55-grain" for the common 5.56 NATO round. The higher the advertised grain weight, the heavier the bullet.

Twist Rate vs. Barrel Length

Twist rate is not typically related to barrel length, and barrel length doesn't usually determine which twist rate is best. Barrel length only determines muzzle velocity. In most cases, if a particular bullet performs best with one twist rate, that rule always applies, regardless of the length of the barrel it's fired from. For example, whether fired from a 16", 20", or 24" barrel, a 77-grain Sierra MatchKing bullet is always best stabilized with a 1:8 twist rate.

There is one key exeption to this rule: In short barrels -- say, 7.5" to 10.5" -- it is acceptable, and sometimes required, to pick a slightly faster twist rate to maintain good stability and accuracy. This is because when significantly reducing barrel length, the total number of rotations a bullet experiences decreases, which can reduce its rate of rotation in flight, effectively reducing its stability.This is particularly true for the .300 AAC Blackout cartridge, which is optimized for very short barrels and chambers dramatically different grain weights in a single caliber.

We cover this and other optimal twist rates for popular AR-15 calibers in detail below.

How to Pick a Twist Rate

Twist rate is just as important for accuracy as barrel steel and barrel length. Unless you exclusively fire one load of a specific grain weight for a particular caliber, you'll have to compromise when selecting a twist rate for your barrel.

A rate that's optimal for a lighter bullet may fail to stabilize a heavier load, causing that bullet to tumble through the air from insufficient spin.

Inversely, a heavier bullet's optimal twist rate could over-stabilize a lighter bullet and cause spin drift, a phenomenem that makes the round to the right from the target (in the direction of rotation).

So, how do you determine the best twist rate to avoid under- and over-stabilization?

Gyroscopic Stability Factor

Gyroscopic stability factor (GSF) indicates what twist rate is best for a bullet's weight. GSFs are displayed using charts to show whether various twist rates are too fast or too slow for a caliber's different bullet weights.

Regardless of caliber or bullet weight, these gyroscopic stability rules apply:

- GSFs below 1 are unstable; bullets will tumble in flight and suffer poor accuracy.

- GSFs between 1.1 and 1.3 are marginally stable; bullets may still tumble in flight.

- GSFs of 1.4 to 2.9 are optimal and provide the best overall accuracy.

- GSFs of 3.0 to 3.4 are suitable for retaining stability at long distances.

- GSFs of 3.5+ may cause some slight spin drift at long distances.

- GSFs of 6.0+ may cause noticeably spin drift with lighter loads.

When compromising on twist rate, it's far better to have a high GSF than a low GSF. Under-stabilization (a value below 1.4) will result in poor accuracy by causing rounds to tumble through the air and keyhole targets. Over-stabilization only becomes a real concern at extreme values (6+) and, for the typical shooter, is rarely a concern.

There is one, final rule that matters most: To obtain the best performance, always try to get as close as possible to a GSF of 2.0 when picking a twist rate your chosen bullet weight.

The Best Twist Rates For Common AR-15 Calibers

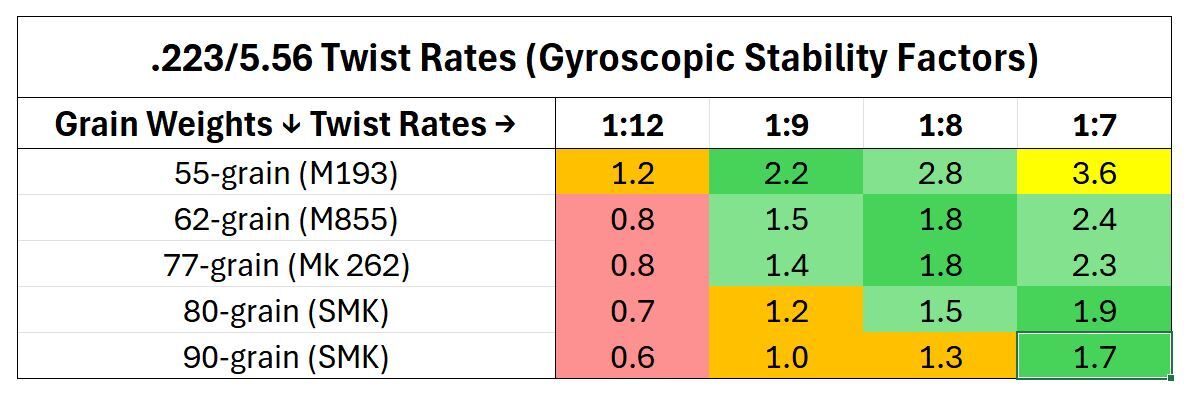

5.56 NATO / .223 Remington Twist Rate Chart

Based on the GSF chart above, we see the optimal twist rates for common 5.56 NATO and .223 Remington bullet weights, each of which gets close to a GSF of 2.0:

- 55-grain: 1:9

- 62-grain: 1:8

- 77-grain: 1:8

- 80-grain: 1:7

- 90-grain: 1:7

The chart above also illustrates why it's better to bias your choice toward higher GSFs if you plan to chamber various grain weights for one caliber: Lighter bullets remain well stabilized and don't approach the extreme limit of a 6.0+ GSF, while even the heaviest loads obtain at least marginal stability (1.0+ GSF).

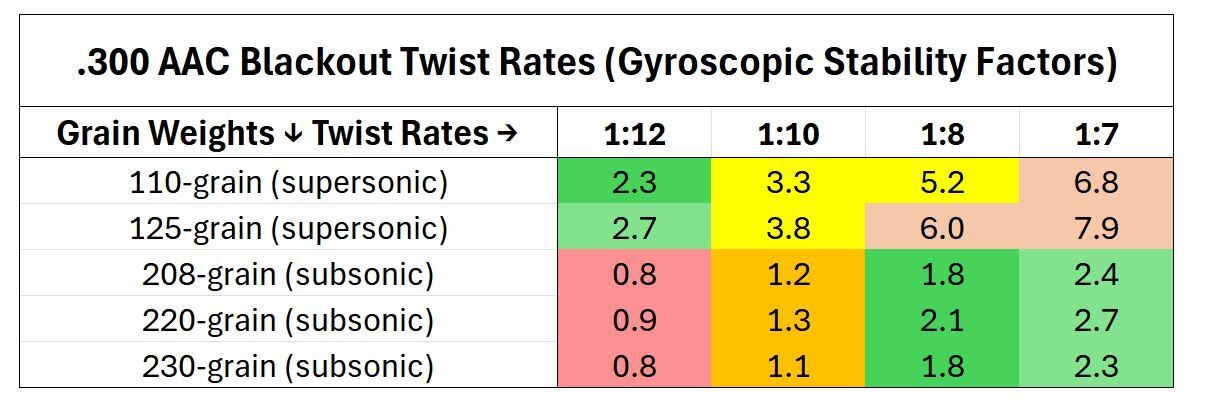

.300 AAC Blackout Twist Rate Chart

Selecting a twist rate for 300 BLK presents a unique challenge. That's because 300 BLK is essentially two different cartridges in one casing. It offers supersonic loads, ranging from 110 to 150 grains, and subsonic loads, ranging from 190 to 240 grains.

We can see the challenge of picking a good twist rate for 300 BLK. Supersonic loads appear to demand a slower twist rate, but those rates some can't stabilize heavy subsonic bullets. Subsonic loads need fast twist rates, which which would normally over-stabilize supersonic bullets.

Despite what this chart shows, the exception about twist rates and barrel lengths that we mentioned earlier holds true. When chambering 300 BLK, it's always best to select a 1:7 twist rate. Although the 1:7 rate appears to produce high GSFs (over 6.0) for supersonic loads, the chambering of those loads in short barrels reduces the rounds' rate of spin in flight, which eliminates the spin drift that would normally be experienced.

Likewise, because subsonic loads are also meant to be fired from short barrels, the twist rate that would normally be acceptable (like 1:12, 1:10 or even 1:8) can, in fact, result in those rounds tumbling in flight from a lack of spin.

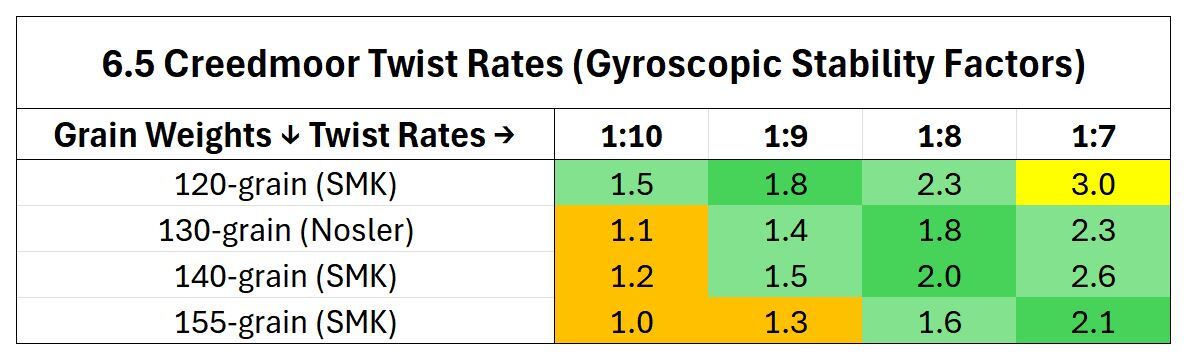

6.5 Creedmoor Twist Rate Chart

One twist rate is optimal for virtually all 6.5 Creedmoor loads: 1:8. This rate provides the best gyroscopic factors for the two most popular bullet weights (130 and 140 grains), while retaining good stability for the heaviest (155-grain) loads, without pushing any lighter loads into high GSF territory.

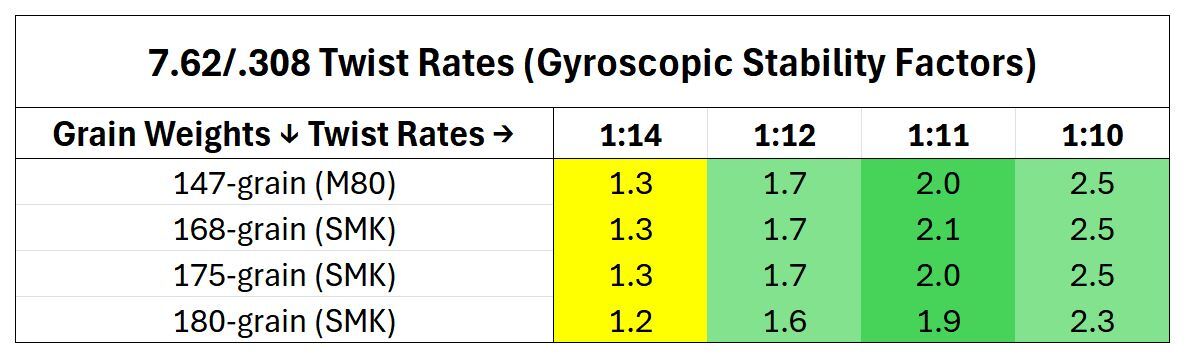

7.62x51 NATO / .308 Winchester Twist Rate Chart

The gyroscopic factors show that a 1:11 twist rate is ideal for 7.62 NATO and .308 Winchester, getting all popular loads right on top of the 2.0 GSF. Keep in mind that these GSFs are based on the use of a 24" barrel. Many shooters who build AR-type rifles chambered in .308 still opt for a 1:10 twist to compensate for the shorter barrels (often 18" to 20") often chosen to reduce length and weight.

Twist Rate Recap

Remember to select a rifling twist that gets your preferred load closest to a gyroscopic stability factor (GSF) of 2.0 Here's a recap of the best twist rates for each popular AR-15 caliber:

- 5.56/.223: 1:8

- 300 BLK: 1:7

- 6.5 Creedmoor: 1:8

- 7.62/.308: 1:11

DISCLAIMER: If you are new to the world of DIY gun building, you likely have a lot of questions and rightfully so. It’s an area that has a lot of questions that, without the correct answers, could have some serious implications. At GunBuilders.com, we are by no means providing this content on our website to serve as legal advice or legal counsel. We encourage each and every builder to perform their own research around their respective State laws as well as educating themselves on the Federal laws. When performing your own research, please be sure that you are getting your information from a reliable source.