Which Type of Barrel Rifling is Best? A Comparison

Posted by 80-Lower.com on Jun 27th 2025

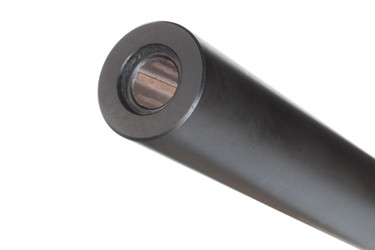

Every shooter wants the most accurate and reliable barrel. If you're building a new AR-15 or just buying a rifle off the shelf, you're probably deciding between different types of rifling: Cold-hammer forged (CHF), cut rifling, and button rifling.

Which one's the best? Is one the best? Each type of rifling offers advantages (and suffers disadvantages) over the others. Let's compare.

Cut Rifling

Cut rifling is best for those who want the most accurate barrel.

Invented in the 16th century, cut rifling was the first method ever developed for turning smoothbore guns into rifles, and it remains one of the preferred rifling methods among high-end and competition barrel makers today. To form cut rifling, a smoothbore barrel blank is inserted into a rifling machine that looks like a lathe.

The barrel is held horizontally in a start-stop rotating assembly while a single cutter, attached to a long rod, is forced through length of the bore. The cutter begins to form one of the rifling's grooves by shaving away just a few thousandths of an inch of steel. The cutter is removed and the barrel barrel is rotated slightly after each cutting pass, allowing the cutter to start forming the next groove.

The barrel rotates, stops for cutting, then rotates again until all grooves have received their first passes, which also begins to form the rifling's lands. The cut-rotate-cut process is repeated until the rifling reaches the desired depth.

Cut Rifling Advantages

Today, cut rifling is what makes the most accurate barrels on the market. Krieger, Bartlein, Lilja, and Proof Research all use cut rifling to make their match-grade barrels. The process is slow and meticulous, ensuring machining tolerances are as precise as possible. Cut rifling is virtually free of any blemishes and deformities, ensuring every round fired yields a consistent spin rate and muzzle velocity to maximize accuracy downrange.

Cut Rifling Disadvantages

Cut rifling is expensive and slow to produce, making these barrels difficult to obtain. Most cut-rifled barrel makers require deposits and weeks- or months-long lead times for a single barrel. Cut rifling also wears more quickly than button rifling and cold-hammer forged rifling. It's more susceptible to degradation from heat and rapid fire, making it a poor choice for most tactical rifles.

But if you're willing to pay the price and wait the long wait, you'll get your hands on a barrel that'll outperform all others at the range.

Cold Hammer Forged Rifling

CHF rifling is best for those who want the most reliable and longest-lasting barrel.

Unlike cut and button rifling -- which both require mostly finished barrels for machining -- cold hammer forging simltaneously forms a rough barrel blank into a nearly finished barrel while also forming the rifling inside the bore.

To cold-hammer forge a barrel, an oversized blank is fitted with a hardened steel bar called a mandrel, which contains a negative impression of the rifling's lands and grooves. The blank is then fed through the forging machine, which uses large power hammers to strike the blank from all sides.

The hammers forge the barrel "cold" (at room temperature), compressing the barrel's steel around the mandrel. This forces the steel inside the barrel to conform to the shape of the mandrel, which stamps the rifling's lands and grooves into the bore. The forging process also reduces the oversized blank's outer diameter, shrinking it to the barrel's final diameter. Only minor machining is required to finish the barrel afterward.

CHF Advantages

Cold hammer forging produces incredibly strong, hardened rifling that can withstand heat and intense firing schedules better than any other type of rifling. The process was originally developed for making machinegun barrels, which are subjected to nearly constant rapid fire.

CHF barrels will outlast cut- and button-rifled barrels by many thousands of rounds. They suffer less throat erosion with each shot fired and maintain accuracy longer. These barrels are also easy to produce quickly, making them generally affordable.

CHF barrels are quite accurate, too. The forging mandrel produces incredibly smooth, uniform lands and grooves that are capable of yielding nearly match-grade accuracy.

CHF Disadvantages

Despite its toughness and uniformity, CHF rifling will simply not be as accurate as cut rifling, and these barrels are almost always more expensive than button-rifled barrels.

Button Rifling

Button rifling is best for those who want the most affordable barrel, while enjoying some aspects of cut and CHF rifling.

Button rifling could be described as a sort cross between cut rifling and cold hammer forging. Button rifling is created by using a tungsten carbide button tool to force the rifling's shape into the bore.

In a manner somewhat like cut rifling, the barrel blank is secured horizontally to the rifling machine while the button is attached to a long rod and pushed through the bore. And, like hammer forging with a mandrel, the button contains a negative impression of the rifling and forces the bore to conform to the button's shape via hydraulic pressure, with all the lands and grooves being formed simultaneously.

Button Rifling Advantages

Using a button is, by far, the quickest and easiest way to produce a barrel's rifling. So, button-rifled barrels are typically far more affordable than cut barrels, and generally more affordable than CHF barrels. Rather than removing steel from the bore, the button compresses the rifling's lands and grooves into shape. This yields a type of work-hardened rifling that, like a CHF barrel, is stronger and more resilient to heat and rapid fire than cut rifling.

So long as the barrel blank and button are precisely machined, the finished rifling in a button barrel is incredibly accurate -- in some cases, nearly as accurate as cut rifling and typically more accurate than CHF rifling.

Top tactical barrel makers like Criterion, Geissele, Ballistic Advantange, and Centurion Arms all produce button barrels that yield sub-MOA accuracy, with greater strength than cut barrels, making them ideal for obtaining long-range accuracy in semiautomatic rifle platforms.

Button Rifling Disadvantages

A button barrel will neither be as tough as a CHF barrel, nor as accurate as a cut barrel. With that said, these are still high-quality, capable, and durable barrels that afford good accuracy and long barrel life, even when subjected to rapid fire.

Ready to Upgrade Your Barrel?

Made a choice and picked a barrel? Now it's time to install it. If you're building or swapping the barrel on your AR-15, follow our instructional guide!

How to Build an AR-15 Upper: Instructions & Photos

DISCLAIMER: If you are new to the world of DIY gun building, you likely have a lot of questions and rightfully so. It’s an area that has a lot of questions that, without the correct answers, could have some serious implications. At GunBuilders.com, we are by no means providing this content on our website to serve as legal advice or legal counsel. We encourage each and every builder to perform their own research around their respective State laws as well as educating themselves on the Federal laws. When performing your own research, please be sure that you are getting your information from a reliable source.