Billet vs. Forged: Which Receivers Are Best?

Posted by 80-Lower.com on Jul 30th 2020

If you're building an AR-15 -- or even just buying one -- you’ve hit this fork in the road: Should you choose billet or forged upper and lower receivers?

It’s a deceptively simple choice that can have a big impact on how your AR performs and how much it costs, and what parts you can install. Let’s break it down.

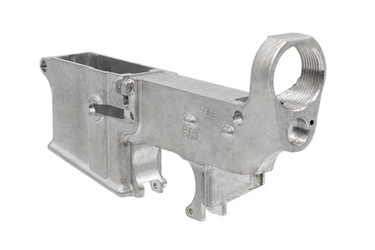

What is a Forged Receiver?

Pictured: A mil-spec forged 80% lower receiver for an AR-15.

Forging is the old-school, mil-spec way to make AR-15 receivers. Take a blank of 7075-T6 aluminum, heat it, smash it into shape under tons of pressure using power hammers, then machine it to the final size and shape.

Benefits of Forged Uppers & Lowers

Shooters love forged receivers for a few reasons:

-

Strength-to-weight king. The forging process aligns the metal’s grain structure, giving it a toughness you can’t get by just carving metal away (like how billet receivers are made).

-

Proven pedigree. Every military-issued M16, M4, and M27 in circulation in the U.S armed forces uses forged receivers. They take abuse, keep running, and shrug off the kind of knocks and abuse that would dent softer billet metals.

-

Light and affordable. No extra fluff means no extra ounces. Forged receivers are physically more compact than billet receivers, offering a greater strength-to-weight ratio. They're also cheap to make, which translates into a lower retail price.

Drawbacks of Forged Uppers & Lowers

There are a few reasons why you might prefer other options when you're picking your upper and lower receivers, and forged units can't offer everything:

- Standardized design: Forged receivers are all virtually identical. No matter the maker, every forged upper and lower receiver has the same, exact design. They're functional and simple, but that also means they don't provide some of the creature comforts and features you might find on a pair of billet receivers.

What is a Billet Receiver?

Pictured: A billet 80% lower with trigger guard and threaded fittings for an AR-15.

A billet lower receiver is cut to shape from a block of 6061-T6 aluminum. This aluminum is easier to cut and drill than 7075-T6 aluminum, which makes it a better candidate for machining.

Benefits of Billet Uppers & Lowers

Cutting receivers from a solid piece of billet aluminum allows for precise machining and custom finishing, among other advantages:

-

Better Features. Adding flared magwells, integrated trigger guards, and custom cuts that reduce weight or add to the aesthetic the receiver are usually only possible with billet receivers. Some billet receivers also make use of threaded fittings that make the installation of certain parts -- like bolt catches and pin retainers -- easier. This also makes them function more reliably.

-

Precision Fit. CNC machining produces incredibly tight tolerances that ensure both receivers' components work perfectly, with pin holes. Because of this precise machining, billet upper and lower receivers often have a much better fit than forged receivers.

-

Premium Finish. The surfaces of forged receivers can suffer from slight inconsistencies in their manufacturing process. That's not the case with billet receivers. Even the aluminum stock used to make billet uppers and lowers is perfectly cut and finished before being turned into a receiver, so there are never any burs, bumps, dents, mis-alignments, or other blemishes in the finish of a billet receiver.

Drawbacks of Billet Uppers & Lowers

Despite their premium fit and finish, billet receivers are not without some disadvantages:

- Lower Strength-to-Weight Ratio: Billet receivers are made from softer aluminum. To make them as strong as forged receivers, they need to be made physically larger, with more material. This adds to the weight of the receivers and, ultimately, the finished rifle.

- More Expensive: The billet manufacturing process is simply longer and costlier. Because of this, billet receivers tend to be more expensive.

- Not Universally Compatible: Because billet receivers don't conform to the "mil-spec" standard like forged receivers, they're not universally compatible with all AR-15 parts. You must ensure your receivers work with certain parts -- like the threads on your buffer tube, or the components in your lower parts kit -- before buying those parts and assembling them.

Which One Should You Pick? Forged or Billet?

This is the age-old question every AR-15 owner and builder asks. The answer's surprisingly simple, though:

If you want a dependable, affordable, tough AR-15, go forged. You can't go wrong with forged upper and lower receivers. You're getting maximum strength, proven reliability, and mil-spec compatibility with all AR-15 parts. You're also saving money.

If you want a custom AR-15 with a premium fit, finish, and features, go billet. Forged receivers can be boring to some, or downright ugly to others. Plus, you miss out on extra features. Billet receivers offer improved aesthetics and added functionality that can make your AR stand out from the rest.

DISCLAIMER: If you are new to the world of DIY gun building, you likely have a lot of questions and rightfully so. It’s an area that has a lot of questions that, without the correct answers, could have some serious implications. At GunBuilders.com, we are by no means providing this content on our website to serve as legal advice or legal counsel. We encourage each and every builder to perform their own research around their respective State laws as well as educating themselves on the Federal laws. When performing your own research, please be sure that you are getting your information from a reliable source.