UPGRADE YOUR BUILD

With These Trending Parts & Accessories

BUILDERS' FAVORITES

You Need These...

-

SaleWas: $74.99Now: $69.99

-

-

Sale

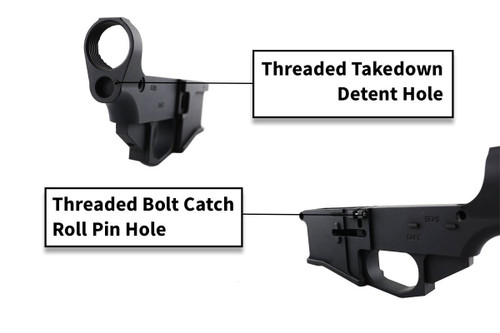

Blemished - 80% Lower Fire/Safe Marked - Anodized Black

Was: $64.99Now: $59.99 -

-

.308 80% Lower - Billet

$119.99 -

-

-

Featured Products

Popular Trending Products

-

-

-

Sale

80% Lower Fire/Safe Marked - Anodized Black

Was: $74.99Now: $69.99 -

Sale

AR9 80% Lower Fire/Safe Marked - 9mm - Billet

Was: $119.99Now: $99.99 -

-

-

Sale

Blemished - 80% Lower Fire/Safe Marked - Billet

Was: $89.99Now: $84.99 -

New Products

Recently Added

-

-

-

-

11-Piece 1911 Pin Set

$24.99 -

Our Story

a little bit about 80% Lowers